A lockout/tagout system is essential to any safety program.

Many hazards can exist across a facility or plant of any size—whether it be electrical, chemical, pneumatic, thermal, gravitational or other energy that can harm personnel. Exposure to hazardous energy is preventable when putting effective safety procedures and training in place that safeguard employees and comply with OSHA’s 1910.147 lockout/tagout (LOTO) standard. Ball Valve Lockout

OSHA’s 1910.147 standard covers the servicing and maintenance of machines and equipment in which the unexpected energization or start-up of the machines or equipment, or release of stored energy, can occur. While the number of LOTO violations has decreased over the last year, it remains one of OSHA’s top-ten most frequently cited violations year-over-year, with 2,606 violations being reported for fiscal year 2018 vs. 2,923 violations reported in fiscal year 2017, according to two Safety + Health Magazine articles from Sept. 2019 and Nov. 2018.

Implementing a best practice LOTO program is an ongoing process that requires routine training and a continuous commitment to safeguarding personnel from the unexpected release of hazardous energy. One commonly used method when isolating energy for maintenance is tagout. On its own, tagout involves the placement of “Danger: Do Not Operate” tags at the energy isolation points to indicate that the equipment is undergoing servicing or maintenance and cannot be operated until the tag is removed.

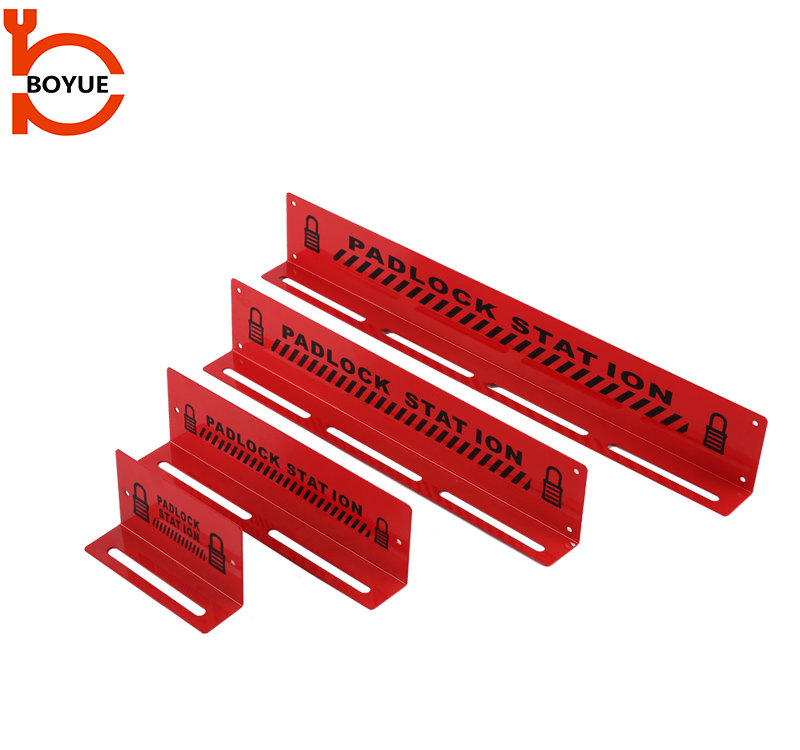

While tagout is a valid method under OSHA regulations for the utility industry, facilities can better safeguard employees by implementing “lockout,” which is the placement of a safety lock and a lockout device on the energy isolation points of a piece of equipment to render it inoperable. Lockout uses a safety padlock to hold an energy isolation device in a de-energized state and prevents the re-energization of the machine or equipment until removed.

Facilities already utilizing a tagout program can enhance employee safety by implementing hazardous energy control that involves both lockout and tagout.

Common Challenges of Implementing an Effective Lockout Program

An effective lockout program is a crucial step in ensuring employee safety, as employees can be seriously or fatally injured if machinery unexpectedly energizes, starts up or releases stored energy. However, only a small percentage of companies have effective lockout programs in place.

This article originally appeared in the November/December 2019 issue of Occupational Health & Safety.

With FitGenius by Aetrex, Lehigh improves performance with a more accurate fit than a traditional in-store try-on.

The Nextteq® Detector Tube and Pump System product line from Nextteq® represents well over 500 unique applications utilizing over 300 different kinds of detector tubes as part of a complete sampling analysis system to detect and measure toxic and combustible gases or vapors and materials. Multiple industries are supported and backed by our in-house staff which incorporates a Certified Industrial Hygienist, a Board-Certified Toxicologist, and a Certified Safety Professional to assist you with your technical questions. 3

Ultra-thin maximum cut protection. Introducing SUPERIOR GLOVE’s thinnest 21-gauge TenActiv™ gloves featuring the industry’s maximum ANSI A9 cut protection. Optimized for touch sensitivity, dexterity, and touchscreen compatibility, they’re ideal for precision tasks that require extreme cut resistance. Engineered at their Canadian headquarters and manufactured in their facilities. Request samples today! 1-800-265-7617. Visit Superior Glove at the ASSP Annual Safety + Conference Expo, BOOTH 1435. 3

Elevate your Lockout Tagout (LOTO) safety game with TRADESAFE Lockout Tagout Station Cabinet—the ultimate safety solution for businesses that prioritize smart, reliable, and efficient safety measures. Featuring 70 LOTO devices, this durable cabinet offers the versatility you need to safely lock out hazardous energy sources during maintenance or repairs. With a spacious interior, you can easily organize and store all your LOTO devices in one place. Order yours today. 3

Accurate Manufacturing Inc. now faces penalties totaling $275,890. Read Now

Ultium Cells LLC faces hefty fines following extensive OSHA investigations. Read Now

Guests can earn continuing education credits while getting the latest safety updates. Read Now

Insights from the survey will inform safety protocols and readiness for future pandemics. Read Now

Attendees at the annual event have plenty of opportunities to connect. Read Now

Padlock Hasp Lock See our Privacy Policy, Cookie Policy and Terms of Use. CA: Do Not Sell My Personal Info