Salvagnini offers the B3.AU-TO press brake, featuring automatic setup and tool change and combining features of electric and hydraulic systems.

The machine is suitable for smaller batches, kit productions, and batch-ones with very short lead times. The automatic tool change and the automatic tool adjuster, which adjusts the length of the stations, reduce the press brake retooling phase to reduce lead time and help increase productivity. 220 Tons Lamination Press

The press brake can be programmed on the machine, using the Face human-machine interface, or in the office with Streamformer software, which automatically creates the bending sequences, setups, and bending stations.

Four models are available, with a maximum bending length of 3 or 4 m and maximum force of 170 or 220 tons.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Set your creative genius free with WARDJet technology. Our machines are renowned around the world for superior industrial-grade systems that cut through the toughest material. See how easy it is to produce beautiful quality custom shapes when cutting architectural glass.

© 2023 FMA Communications Canada, Inc. All rights reserved.

1154 Warden Avenue Suite #416, Toronto, Ontario M1R 0A1

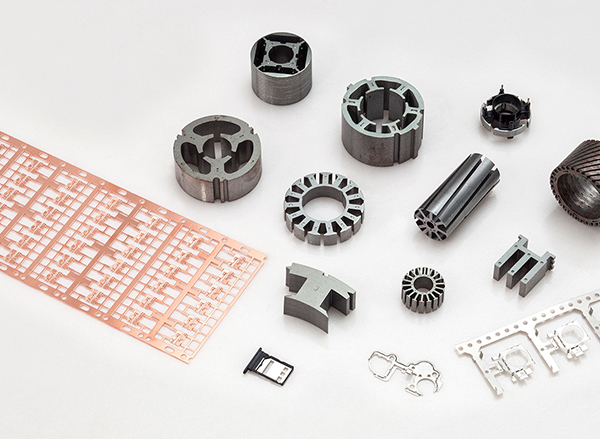

Metal Stamping Equipment Not yet registered? Sign up