The new plant offers a re-manufacturing process, taking magnets from end-of-life electric motors, electronic waste and components, reclaiming neodymium, iron and boron and reforming it back into commercial-grade magnetic materials.

Professor Allan Walton, co-director of the Birmingham Centre for Strategic Elements and Critical Materials at the university, says: ‘This pilot plant paves the way for the UK to take a leading role in high performance magnet recycling. As less than 5% of end-of-life magnets are currently recycled, this is a key process that can begin to address the global shortfall in magnet manufacture.’ Magnet Supplier

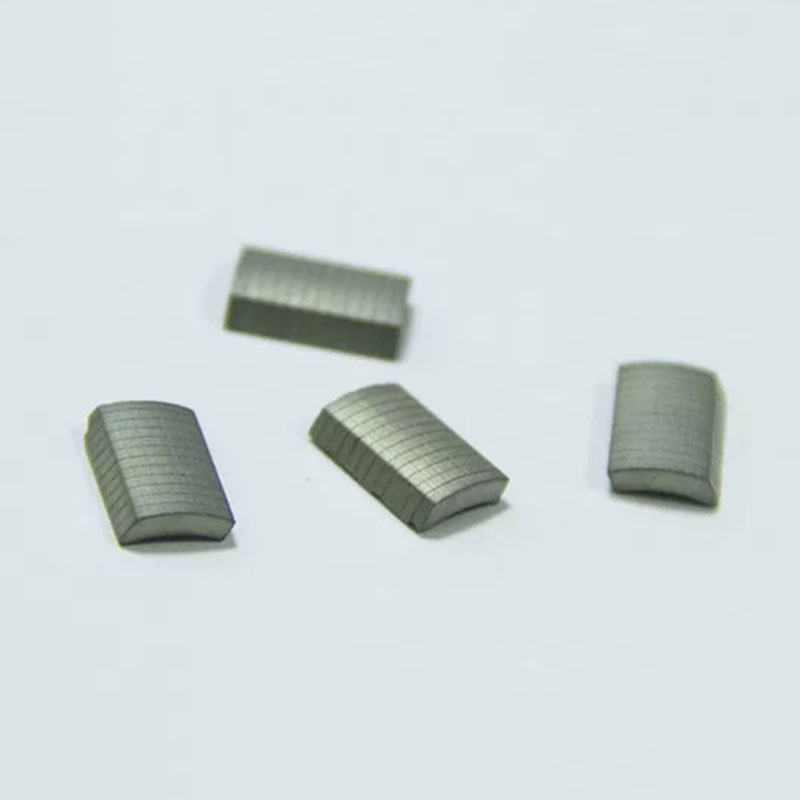

In the new facility, a 1 200-litre pressure vessel can process up to 100 kg of magnets per day. The resulting powder is de-magnetised during this process, so can then be refined further before going through a pressing and sintering process, in which the reclaimed materials are compacted and heated to form new magnets.

In doing so, this process uses 88% less energy to create magnets when compared to virgin sources and will offer the only indigenous source of sintered rare earth magnets in the UK.

The plant is seen as an important step towards opening the UK’s first full scale remanufacturing facility at Tyseley Energy Park in Birmingham to be completed in 2023.

Don't hesitate to contact us to share your input and ideas. Subscribe to the magazine or (free) newsletter.

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed.

How long has your company been in the recycling business?

Disc Smco Magnet Stay on top of developments across the markets with our weekly newsletter.