CWP has introduced a servo piloting head and roll lift for its combination feeder/straighteners. Photo courtesy of CWP

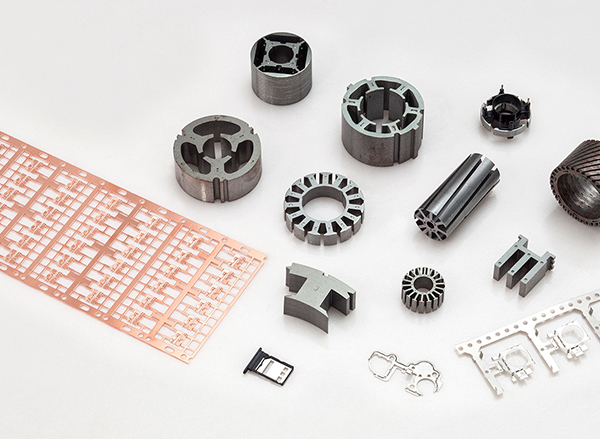

At least eight press feed challenges that plague stamping manufacturers are now being addressed with the most updated press feed equipment and systems. Punching Machine

Challenges stamping manufacturers face related to a dearth of skilled workers are not isolated to press operations; they begin at the press feed. Advanced high-strength materials are as difficult to manage in press feeding as they are to form in the press.

Servo press technology brings forming flexibility to address high-strength materials problems but can complicate feed operations.

Pressures for higher productivity are always present, but speed cannot come at the expense of quality. Customer demands for zero defects equate to tighter quality control.

Stampers need nimble flexibility in their feed equipment to adapt to a rapidly changing production environment.

Can multiton machinery ever be too safe? Is there such a predicament as having too much space? Thought not.

Today’s press feed equipment has been developed to help stampers address these challenges. Experts from feed systems OEMs Coe Press Equipment; Cooper-Weymouth, Peterson; and Dallas Industries explain how they have introduced new feed equipment capabilities to help stampers meet those challenges head-on.

“As a generation of experienced workers ease into retirement, a new generation of workers step into their roles,” said Coe Press Equipment President Reid Coe.

This challenge can have a positive side, Coe maintains. “This is a prime opportunity for manufacturers to break the old-tech cycle. Bringing a new workforce into a modern, high-tech environment can create a new norm of safer, more efficient processes.

“We have packaged our standard controls to be rich in features but simple to navigate.”

Coe Press Equipment’s new PLCs have user-friendly screens with pictorial cues, simulation, and automated functions to reduce setup and operation time. Image courtesy of Coe Press Equipment, Sterling Heights, Mich.

Coe Press Equipment’s next-generation PLCs have multiple advanced features designed to significantly reduce the time required to use the feeder. A new, user-friendly HMI guides operators through the setup process logically. Intuitive, pictorial main menus guide them as they navigate machine-specific control screens by selecting an image of the machine they want to operate. Key to the new controls is a 10-inch touchscreen that makes it easy to enter machine setup information.

“Our process-oriented and pictorial menus have been met with enthusiasm from both operators and plant leadership. These improvements make processes easier and more efficient,” Coe said.

Also, the company’s work roll adviser and feed roll adviser software now are embedded into the controls, contributing to simplified setup and changeover.

New simulation features include loop simulation, which shows how the straightener reacts to changes from the feed; press simulation that shows strokes per minute (SPM) changes, feed angles, pilot, start feed, and the stroke at bottom dead center; and work roll simulation, a visual guide to help operators see what’s happening inside the straightener.

The control also has on-the-fly capabilities, and it automatically changes feed speed to adapt to press speed changes. In addition, it can automate straightener setup and feed setup.

A smart speed function automatically adjusts to optimal line speed based on the press speed and feed window. This requires an Ethernet connection with the press, Coe relayed.

Another aspect of the skilled worker shortage are difficulties in getting repeatable results from a feed line setup because operators are often less experienced than in years past, said John Heuring, regional sales manager for Dallas Industries.

In response, the company has added more automated setup axes to the feed line so that more adjustments are controlled via the job recipe, Heuring said. “Dallas uses a system called AutoSet to allow the line to automatically position any or all of the following points: feeder passline height, pilot roll lift height, and edge guides; straightener rolls and edge guides; and uncoiler brake control and coil centering via coil guide rolls,” Heuring said.

“In addition, we have added a straightener roll calculator to the AutoSet package,” he said. The operator inputs the material width, thickness, type, and yield and the straightener roll calculator suggests accurate roll settings for removing coil set that then can be stored in a job recipe, Heuring explained. “The calculator has proven to be very accurate and has been welcomed by our customers.”

Stampers need feeding and straightening equipment that can successfully process advanced high-strength steel (AHSS) and high-strength aluminum used in many automotive applications, Heuring said.

Coe Press Equipment redesigned its heavy-duty (HD) servo roll feeds to be more robust and capable of handling thicker materials. Photo courtesy of Coe Press Equipment, Sterling Heights, Mich.

“Many feed builders have recently updated their straightener designs to address the higher yield points of AHSS. Thankfully, Dallas’ straighteners were already built with many of these features for decades,” he continued. These features include high-torque screw jacks for adjusting straightener rolls, wide-faced gears, large roller journals, and outboard journal supports. “In recent years we updated our straightener backup design to a ‘Hi-Flight’ style with wider backup rolls (single or double row) to further enhance the straightener’s ability to run AHSS,” Heuring said.

Coe Press Equipment redesigned its heavy-duty (HD) servo roll feeds in 2019 to increase speeds and precision and decrease cost of operation while being more robust and capable of handling thicker materials, the company said. The modular design is engineered to ease maintenance and the flexibility to reconfigure machine options. Design changes included a 15% increase in journal and bearings sizes, enabling the feeds to handle material thicknesses up to 0.750 in.

In addition, the company introduced its HD servo piloting feeds last year. They are programmable so that stampers can optimize the feed window and the pilot-release window for each die. These systems can process a variety of heavy-gauge materials, including advanced steels. Designed for high-speed environments, the larger journal and bearing sizes can deliver high torque, speed, and accuracy, the manufacturer states. The feeds have a response time of 5 milliseconds, the company says.

Cooper-Weymouth, Peterson (CWP) is addressing challenges related to servo press technology synchronization with new feed technology that is based on time instead of degrees. “Unlike a mechanical press that must complete a revolution before stamping the next part, a servo press can engage the material as soon as it is in position. By communicating the actual feed/move time to the servo press, a very efficient utilization of cycle/part production can be accomplished automatically within the servo press control,” said CWP National Sales Manager Kevin Enos.

CWP has developed an alternative method of syncing an automatic feeder with a press, called servo sensor, that stops feeding automatically when it sees a registration mark.

Dallas’ Heuring said that stampers are striving to maximize a servo press’s versatility via the feed line.

“Making sure to have a flexible (Ethernet-based) controls architecture is a good start,” he said. Dallas often uses a complete Allen-Bradley controls platform that employs A-B HMIs, PLCs, and drives. This means the motion is controlled over Ethernet.” The company uses this architecture and its software to control the feed motion, loop height, axes automation, and brake control to effectively tune the line so that it runs smoothly.

On its combination ServoMax servo feeder/straighteners, CWP has introduced a servo piloting head and roll lift. This allows stampers to increase the straightener head roll lift speed for pilot pin registration. In turn, system production output can be doubled or even tripled, based on the application. While a feeder/straightener with a pneumatic straightener head lift for piloting might attain no more than 60 SPM because of the limitations of the pneumatic piloting operation, a servo piloting head system can reach up to 180 SPM.

A side benefit of this technology is that it reduces plant compressed air usage because it doesn’t use compressed air in the roll lift and piloting operation.

Dallas introduced its new card reader that is designed to control levels of security access for its Allen-Bradley automated feed line, according to Dallas Industries CEO Willie Chacko and John Heuring.

Coe’s HD servo-piloting feeds have a 5-millisecond response time. Image courtesy of Coe Press Equipment.

“We have added an optional access control card reader to our feed lines,” Chacko said. With a swipe of a magnetic strip card, a person can gain any of four levels of access to the machine. The system maintains a log of access so there is a history of who made what changes and when. “With all the automation that is available today, it’s critical to secure the data that is available for each job,” Chacko said.

Heuring explained how the badge access system works.

Level 0 allows an operator to run a preprogrammed job and auto setup axes to job values. Level 1 permits the operator to adjust edge guides and recipe-controlled axes. Level 2 allows the technician to program all the job parameters, press strokes per minute, feed window, feed progression, passline height, material width, straightening roll adjustment, and width of the coil guides and motorized keepers. At the highest level, level 3, the manager or operator can modify machine setup parameters and add or remove user access.

“This replaces password-protected elements of the feed line control as these passwords are often shared and lose their effectiveness quickly,” Heuring said.

Stamping manufacturers need flexibility to excel in a rapidly changing manufacturing environment, CWP’s Enos said. The OEM has implemented a traversing feed to accommodate the feeding of blanks into a press that is normally coil-fed. The traversing feeder can roll in and out of the way to allow for a destacker to be rolled into the press entry. It uses the same tracks and locking mechanisms so that stampers can switch from running coils to running blanks in a matter of minutes.

This capability provides the versatility to run small production part quantities with a destacker and also large batches using a coil feed on one stamping press. Blank feeding can also eliminate the cutoff tooling in the first operation, which can allow parts to be manufactured on a press that might be too small—tonnage-wise or bed size-wise.

The addition of technologies like safe torque off and safe limited speed enhances operator and machinery protection, Enos said. Safe torque off is used to prevent unexpected motor rotation while the drive remains connected to the power supply in the event of an emergency.

Safe limited speed ensures the transition from the operating speed in automatic mode to the reduced speed in setup mode. If the monitoring function detects that the limit value has been violated, the drive will be shut down safely.

Dallas Industries offers the UnderLoop SpaceSaver™ feed line. It comprises a reconfigured threading system with a servo-driven synthetic tension roll, lower threading table, and rocker-arm debending assembly. Also included are powered coil guide rolls that eliminate the need for slide-on coil keepers.

The servo feed with pull-through straightener has pilot release for both the upper feed and straightener rolls, making the line suitable for progressive die applications. The system can have a footprint as short as 18 ft. because of the slack loop being developed under the coil reel. It is available with or without a load car.

Dallas Industries’ UnderLoop SpaceSaver feed line can have a footprint as short as 18 ft. (At left.) AutoSet allows automated setup so that more adjustments are controlled via the job recipe. Photo courtesy of Dallas Industries, Troy, Mich.

Coe expressed concern for what he called a resistance to new technology and process improvements. “Many companies default to ordering a new machine just like the last one or disregard new machine features because ‘What we have works fine.’

“Old technology tends to linger in the stamping world,” Coe continued. Presses and feed equipment are built to be mechanically robust to survive the demands of a stamping operation, but the result is that equipment often stays in operation for even 30 years! “This is nearly unheard of in other segments of industry.

“Unfortunately, the durability of antique machinery makes manual and inefficient processes the norm in many plants,” he said.

Press feeding equipment trends include simpler-to-operate features, more versatility, and tougher builds to help stampers confront forming challenges such as the need to train workers faster, manage tougher materials, and do more with less. Photo courtesy of CWP, Clinton, Maine

See More by Kate Bachman

Kate Bachman is a contributing editor for The FABRICATOR editor. Bachman has more than 20 years of experience as a writer and editor in the manufacturing and other industries.

Find The Fabricator on Facebook

Find The Fabricator on Twitter

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube & Pipe Journal.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator en Español.

Shanen Aranmor says she was once described as a life coach under a welding helmet. She's taken that...

© 2023 FMA Communications, Inc. All rights reserved.

200 Tons Lamination Press Not yet registered? Sign up